Dimensional inspection is key to implementing long-term solutions for manufacturing process issues. Despite robust quality control, issues may arise post-delivery. Leveraging historical 3D measurements is a game changer, facilitating quick issue identification, planning repairs, enhancing future designs, and safeguarding against the financial risks of warranty claims.

For quality control teams, creating inspection projects from the measurement plan requires time-consuming manual tasks and interpreting dimensional requirements from 2D drawings, 3D CAD models, and additional specifications documents.

Discover how the latest version of the PolyWorks|Inspector™ Gauge R&R workflow lets you certify and improve your 3D measurement process performed through its universal metrology platform.

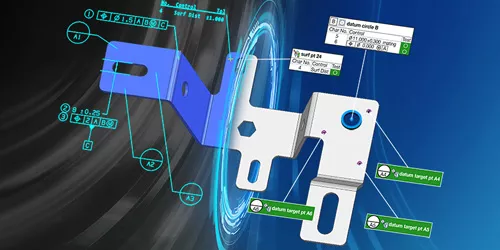

Learn how to integrate a CAD model revision with PMI within a piece measurement template in PolyWorks|Inspector™ in minutes instead of hours, using our PolyWorks|PMI+Loop™ MBD solution for CAD software.

See how operators can measure large parts more efficiently by scanning with near-me guidance, reviewing inspection results directly on the part, and collaborating with colleagues anywhere via MS Teams using the Microsoft HoloLens smart glasses and PolyWorks|AR™ 2023.

Discover how the inspection project data lifecycles delivered by the PolyWorks Digital Ecosystem accelerate the engineering phase of a new product, automate the propagation of CAD design changes, and help build strong long-term know-how and expertise within a manufacturing organization.

Learn how to successfully build and inspect large-scale precision fixtures and tooling for manufactured parts by combining PolyWorks|Inspector™, the PolyWorks|AR™ mixed reality solution, and the FARO® Vantage Max Laser Tracker.

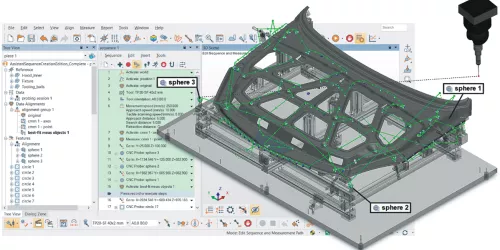

Discover how to create complete CNC CMM measurement sequences in minutes while staying in control with PolyWorks|Inspector™, the universal 3D dimensional analysis and quality control software solution.

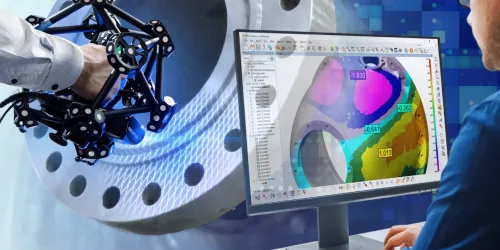

Learn how PolyWorks|Inspector™ and Creaform MetraSCAN 3D can improve your measurement workflow and increase your inspection capacity.

See how improve your inspection workflows with repeatable measurement processes and 3D data capture optimized for accuracy and speed by combining PolyWorks|Inspector™ and the FARO® Quantum Max ScanArm.

Discover how to perform multipiece feature-based inspections without a usable CAD representation more efficiently, with probing guidance plus feature scanning guidance and automatic feature extraction, thanks to the measurement guides technology introduced in PolyWorks|Inspector™ 2022.

Transform collision-free 3-axis CNC CMM sequences into optimal 5-axis sequences by efficiently integrating 5-axis moves and head touch probing.

See how measurement operators can execute probing workflows more efficiently by displaying guidance arrows, measurement instructions, probed points, and common probing functionalities before their eyes using the Microsoft HoloLens smart glasses and PolyWorks|AR™ 2022.

Discover how manufacturing companies can gradually deploy the PolyWorks 3D metrology digital ecosystem to avoid disturbing operations and obtain efficiency gains at every step of their digital transformation journey.

Discover how to efficiently perform a multipiece dimensional analysis on complex geometries using PolyWorks|Inspector™ controlling powerful Hexagon SLS scanners and turntables.

Discover how manufacturing companies can perform root cause analyses of urgent dimensional control issues significantly faster by accessing 3D metrology data and results in real time with PolyWorks|DataLoop™.

Learn how PolyWorks|AR™, a PolyWorks|Inspector™ mixed reality plug-in for the Microsoft HoloLens smart glasses, radically transforms the experience of measurement operators by superimposing vivid holograms on physical pieces and assemblies.

To obtain trustworthy results, a measurement system analysis (MSA) is performed prior to production through repeatability and Gauge R&R studies. InnovMetric proposes an easy-to-use and fully integrated software solution to perform these studies.